DESIGN OVERVIEW

- Epoxy finish floors in core area, all floor edges are coved & polished to minimize dust and dirt adherences.

- All the electrical and utility lines are either taken outside or concealed with in the walls or false sealing.

- All the luminaries are flushed with the ceiling and electrical control panels and the switches are flushed with the walls

- The corridors & windows are designed to enhance the viewing of the manufacturing operations without physically entering the processing areas.

- Materials are stored as per there storage conditions.

- Illumination of all the manufacturing areas has designed to meet standard, taking care of lumens.

- There is pest and rodent control program for the facility and all entry points to the plant are provided with the insectocutor and air curtains.

- Fire extinguisher is located throughout the facility.

- There are emergency exits at suitable places.

- Packing areas construction and finishing of the primary packaging areas is similar to process areas.

- Secondary packaging areas have plastered bricks walls with smooth paint finish.

- The roof is RCC; floor is of granite polished stone.

Approved

Under Approval

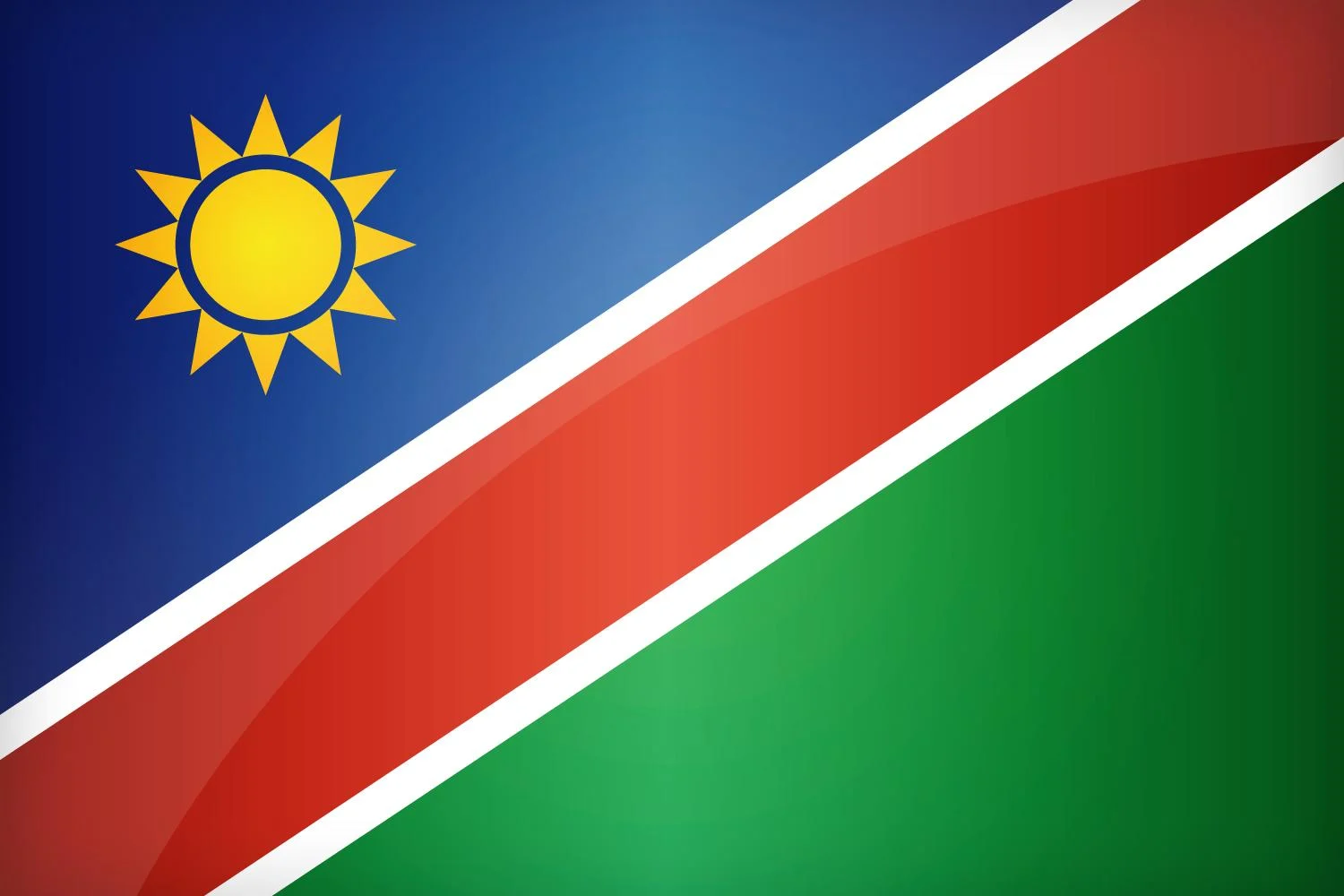

Namibia

Tanzania

| LIQUID | 2 MILLION BOTTLES PER MONTH |

| SACHET | 2 MILLION SACHET PER MONTH |

| CAPSULES | 10 MILLION PER MONTH |

| TABLETS | 60 MILLION PER MONTH |

Tablets (General Category)

- Immediate Release

- Sustained Release

- Extended Release

- Delayed Release

- Enteric Coated

- Oral Dispersible Tablet (ODT)

- Mouth Dissolving tablet (MD)

- Modified release

Capsules

- Delayed Release

- Sustained Release

- Enteric Release

- Tablet in capsule

- Tablet and Granules in Capsule

- Immediate Release

Sachets

- ODT Sachet

- Mouth Dissolving Sachet

- Micro Pellets (where use of active is less than 1 gm per dose) – Montelukast Sachet, Esomeprazole Sachet.